Projects

Industry 4.0 IoT automation project for “Drier out weighting system

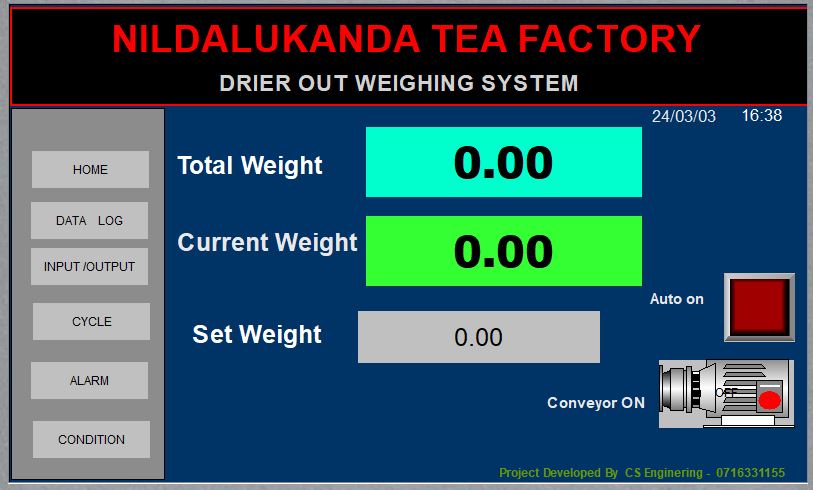

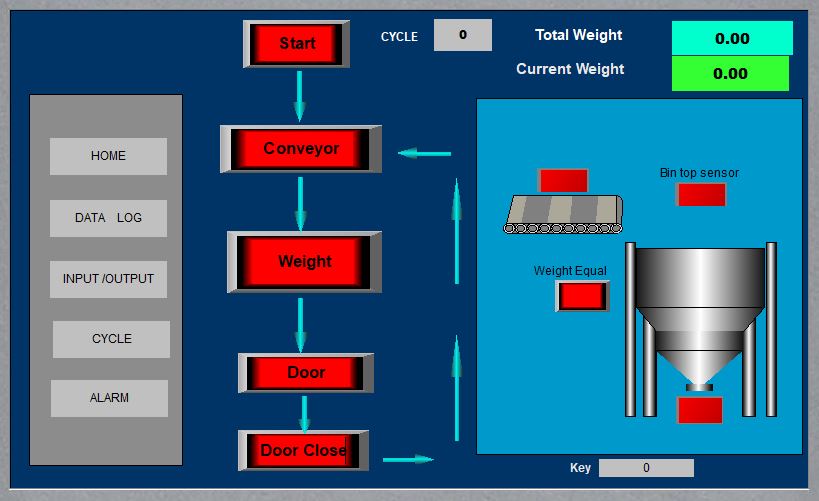

Successfully completed Industry 4.0 IoT automation project “Drier out weighting system” at Tea Factory in Sri lanka. This innovative system automates the final tea production process, accurately weighing and sorting the tea according to specific criteria.

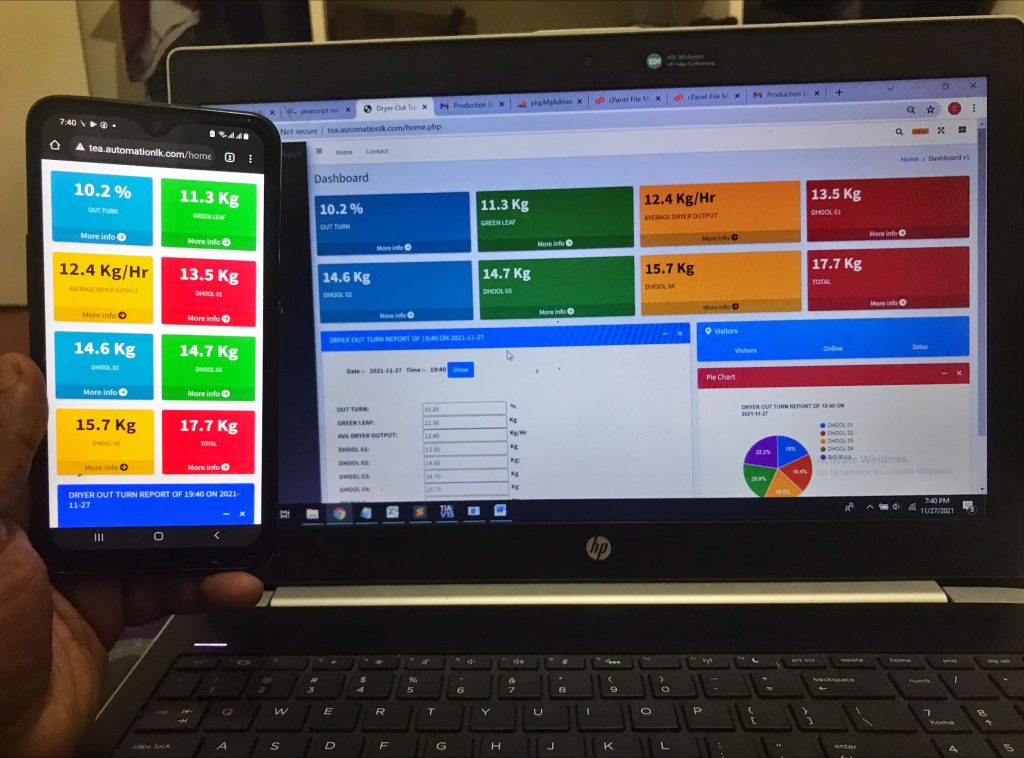

Through our integrated web application, Dextop App and mobile app, stakeholders can conveniently monitor real-time production data. Furthermore, all production data is securely stored on a cloud-based web server for easy access and analysis.

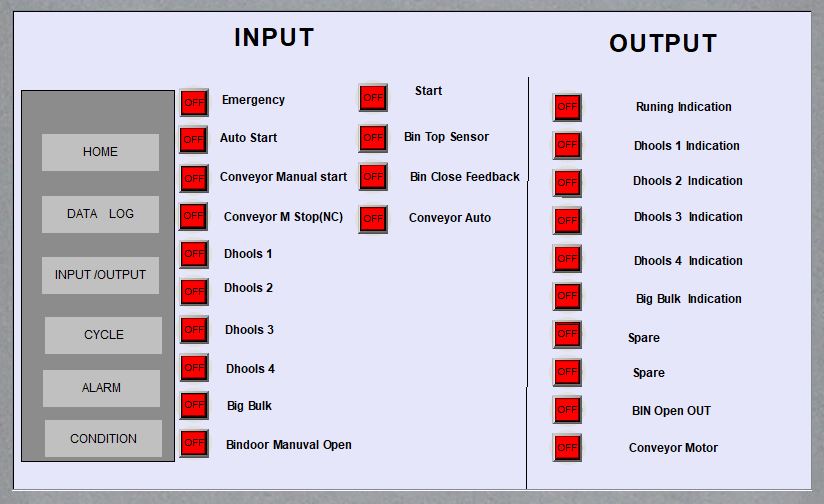

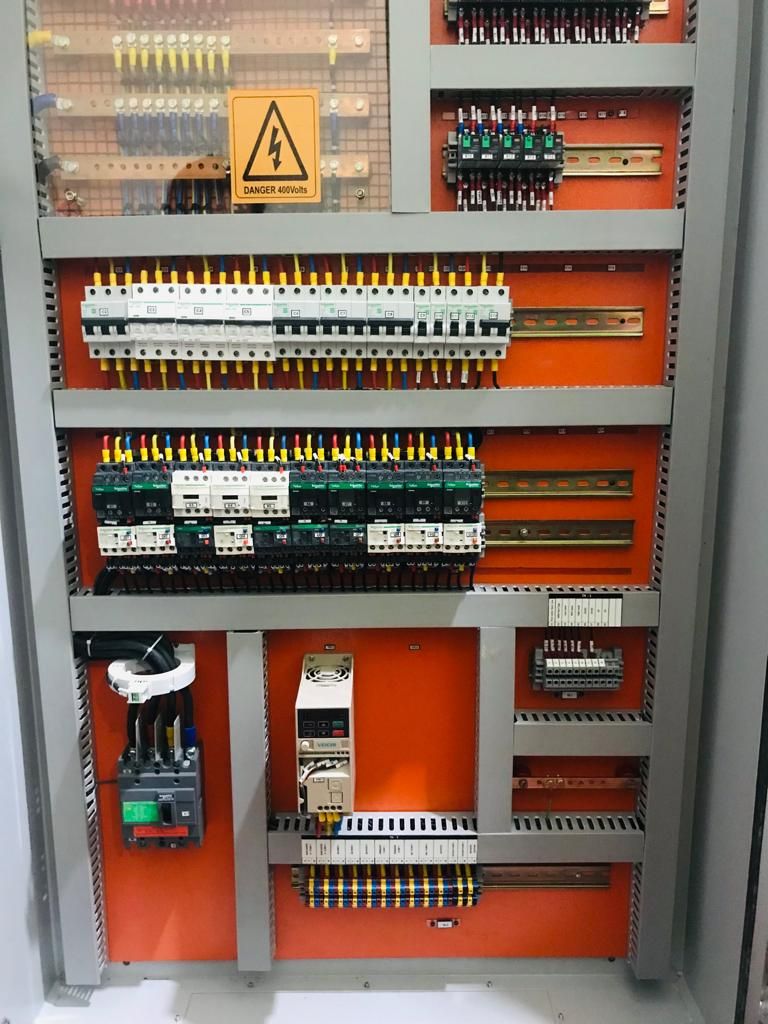

This automation plant include SIEMENS S7 1200 PLC , Unimat 7 inch HMI and Weighting module with load cells. There is the Modbus Rs485 communication between PLC and Weighting module.

In developing this IoT application, we utilized a range of applications and programming languages, including TIA Portal 17, C#, PHP, HTML, CSS, JavaScript, and AJAX. This comprehensive approach enabled us to deliver a robust and user-friendly solution that meets the evolving needs of modern industrial environments.

#PLC Automation, #Tea factory Automation, # Drier out weighting system #S7 1200 PLC #Tia Portal #Electrical Penal board, #SIEMENS Automation, #Electrical engineering, #Automation Engineer #IoT, #Industry 4.0 #Automation

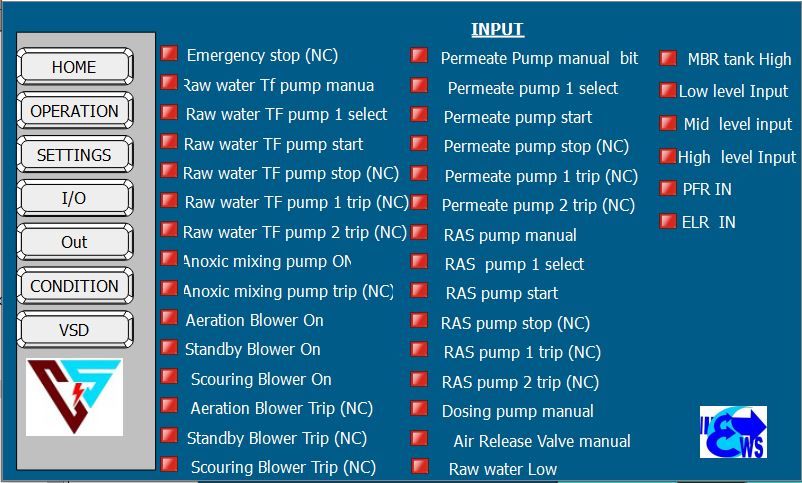

Automation project MBR Sewage Treatment plant at Rockland Distillery Bottling Plant , Hanwella, Sri Lanka

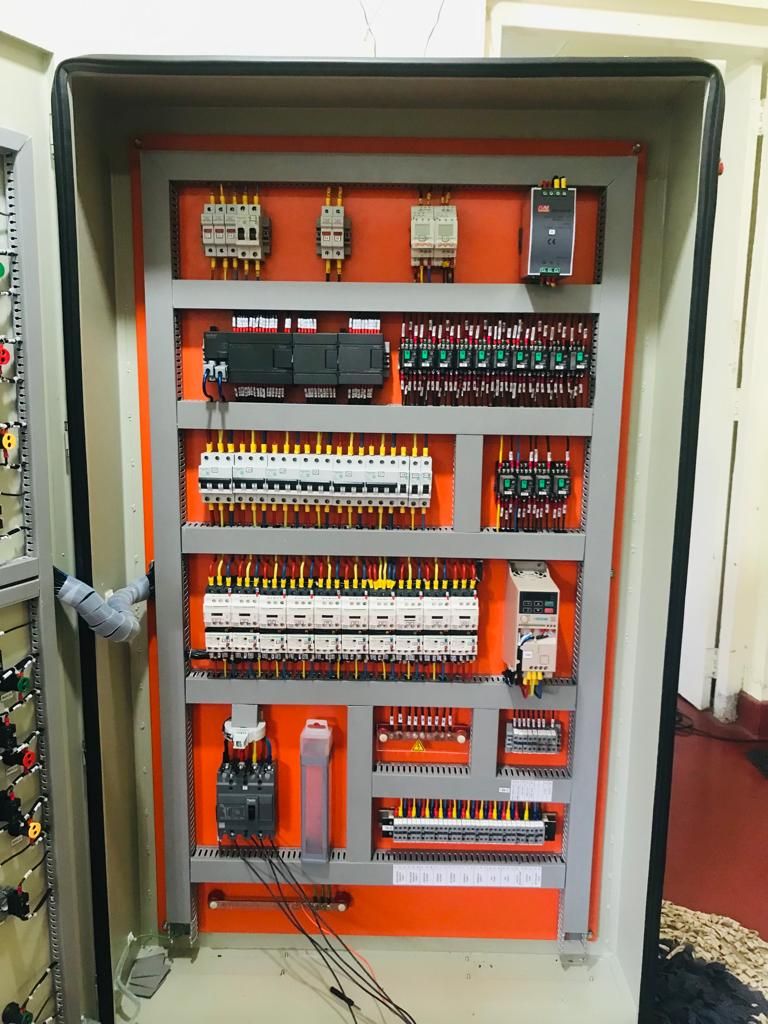

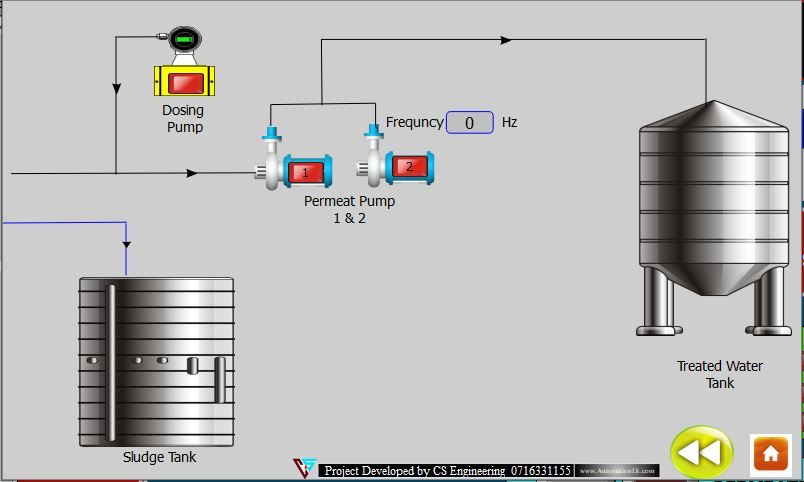

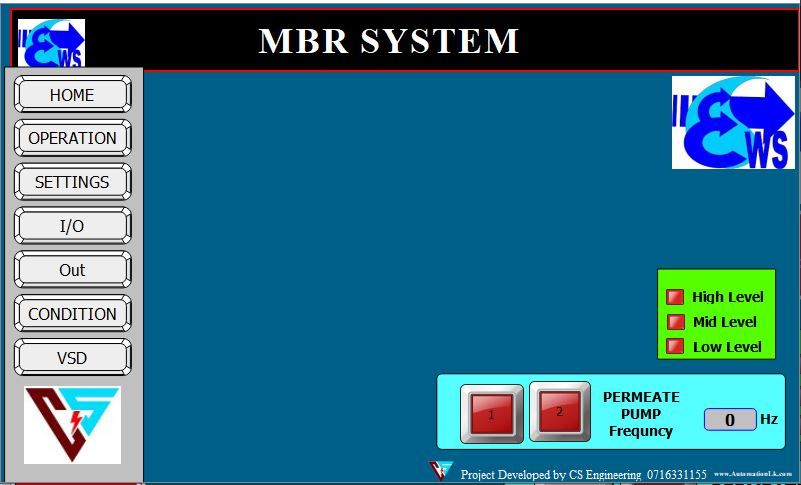

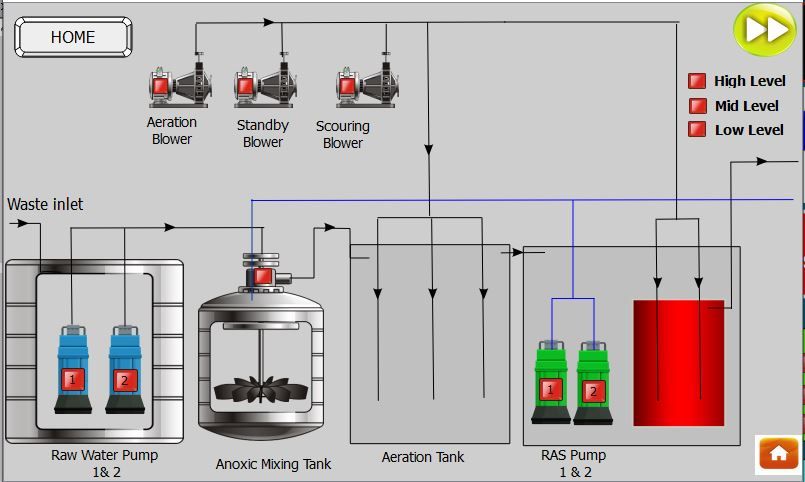

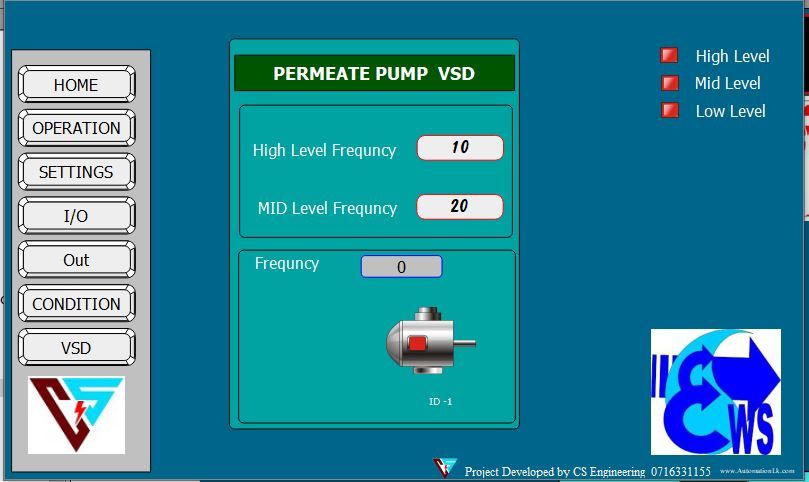

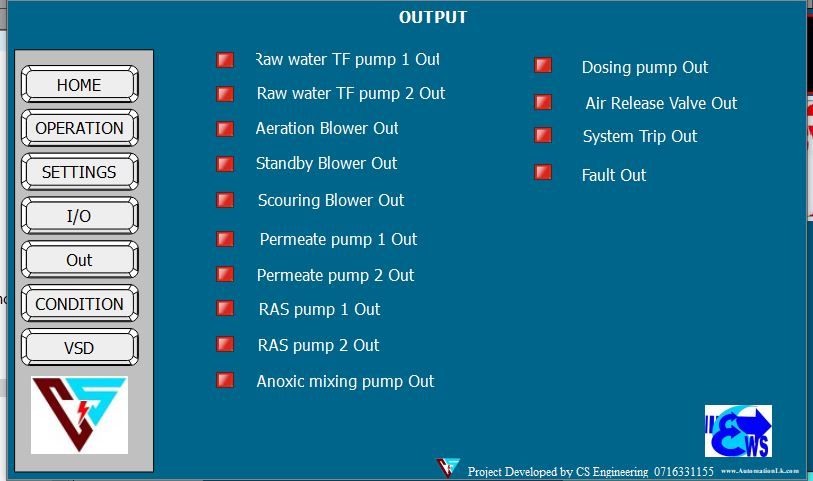

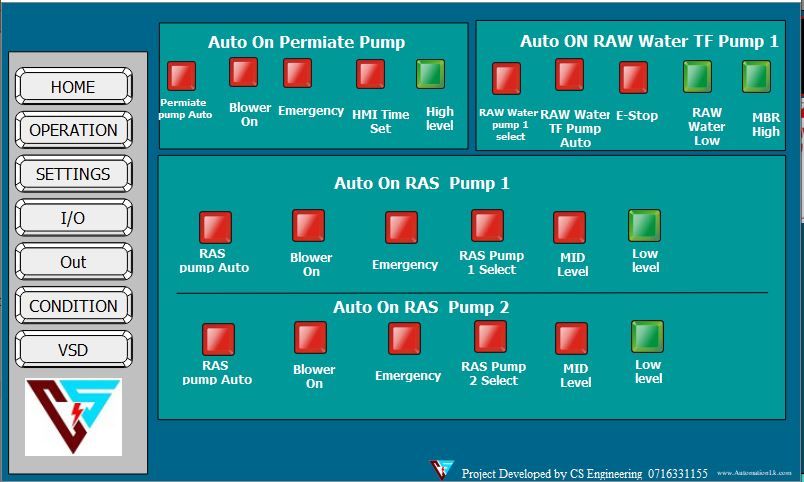

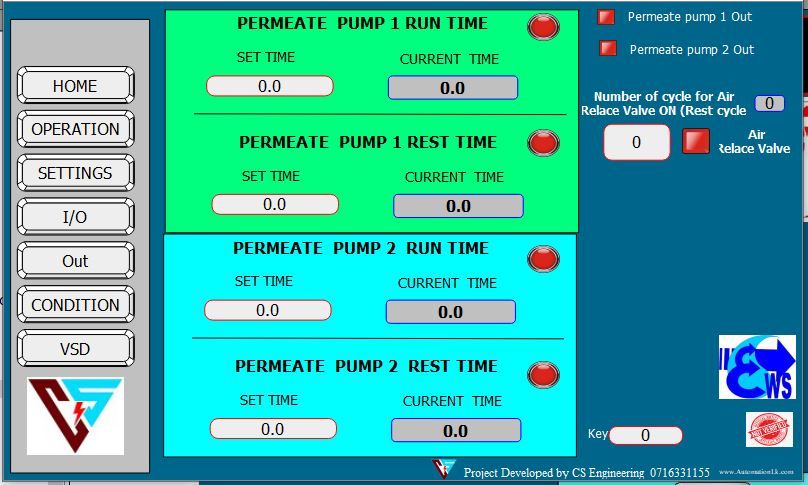

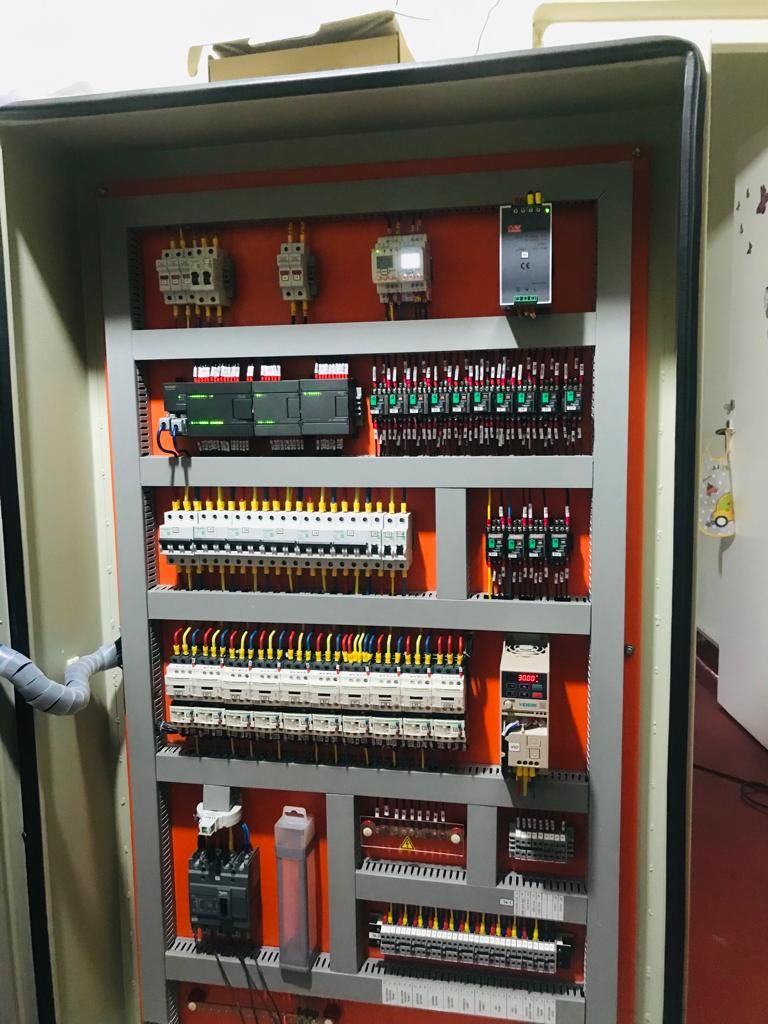

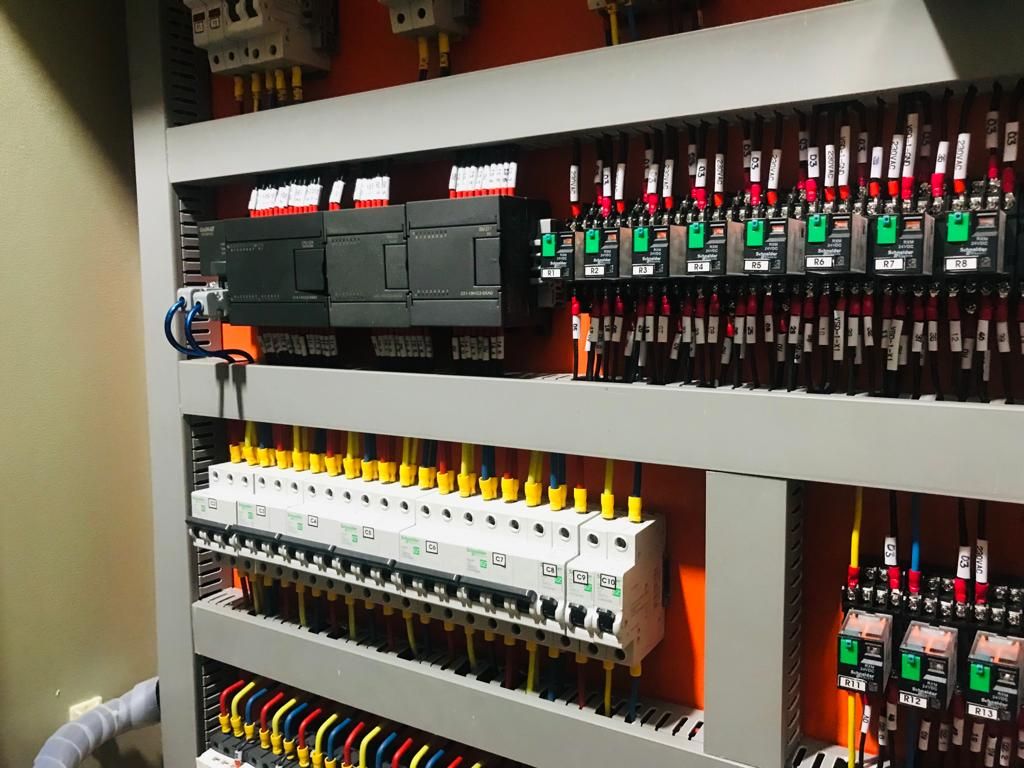

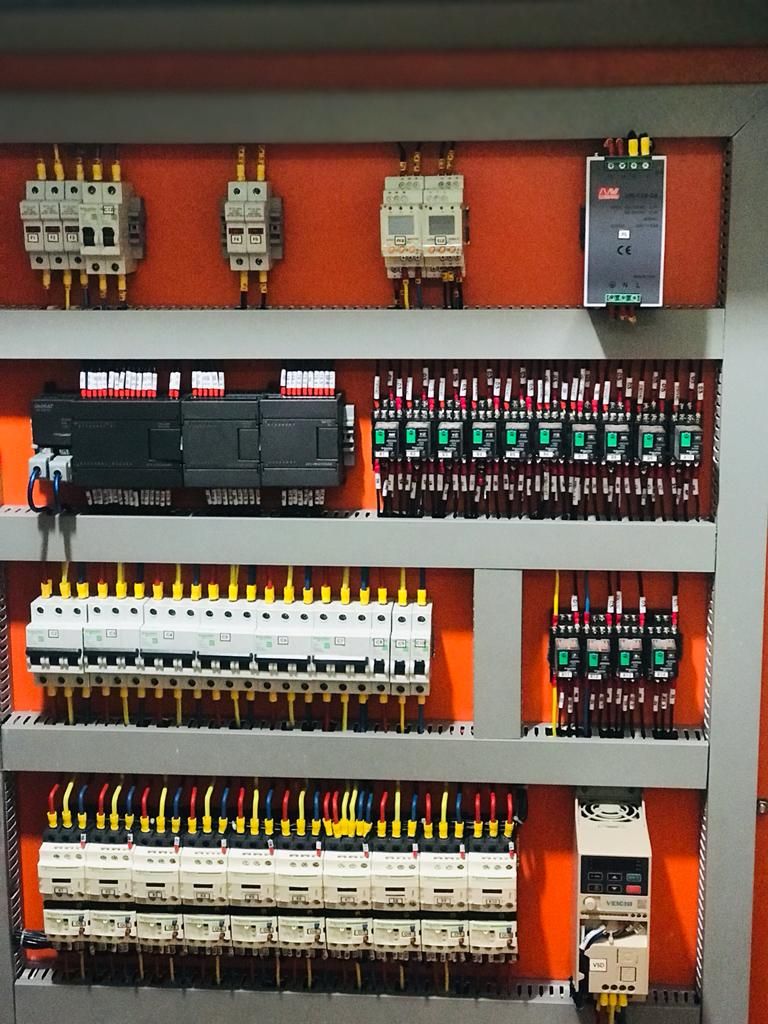

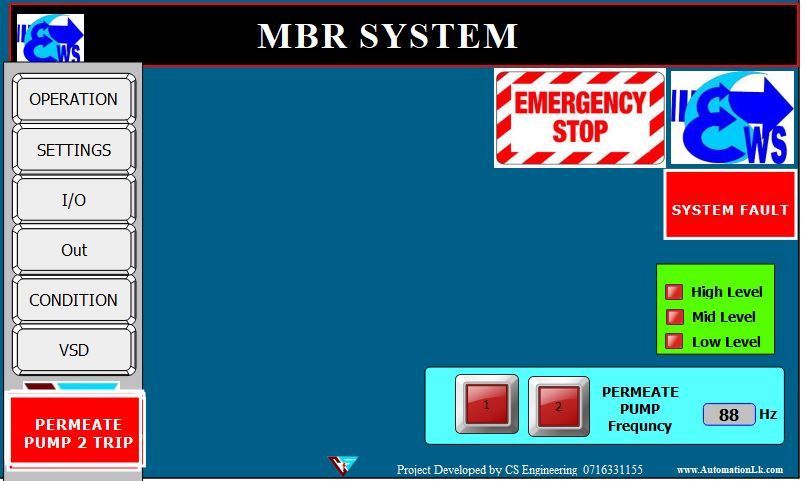

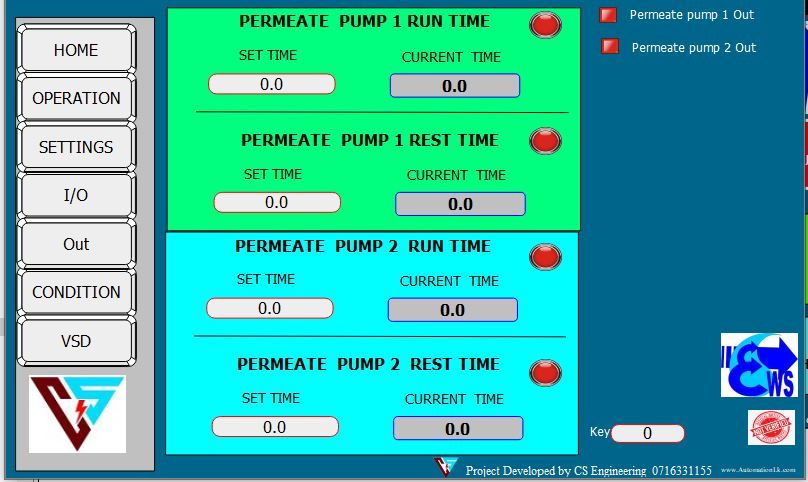

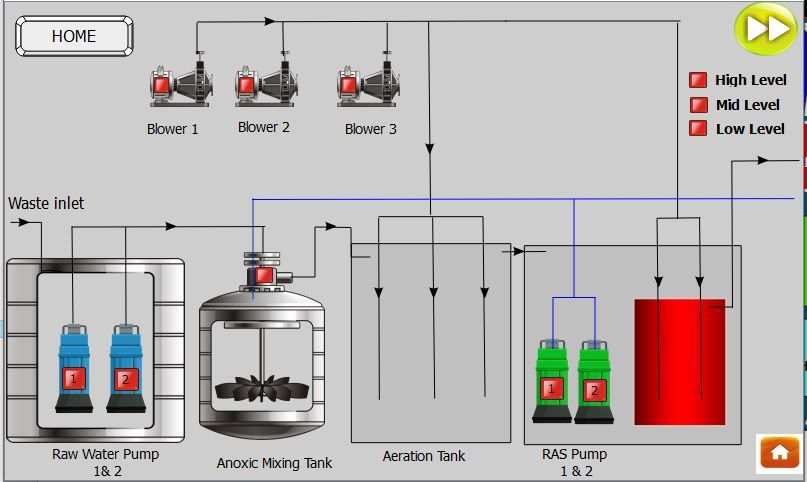

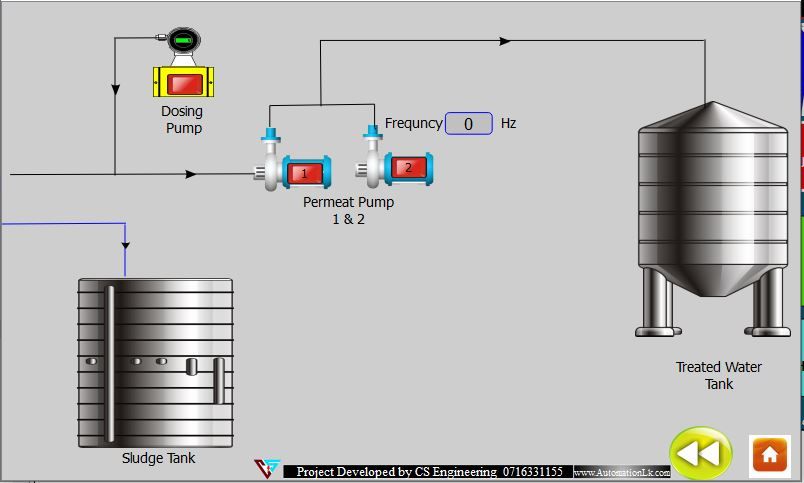

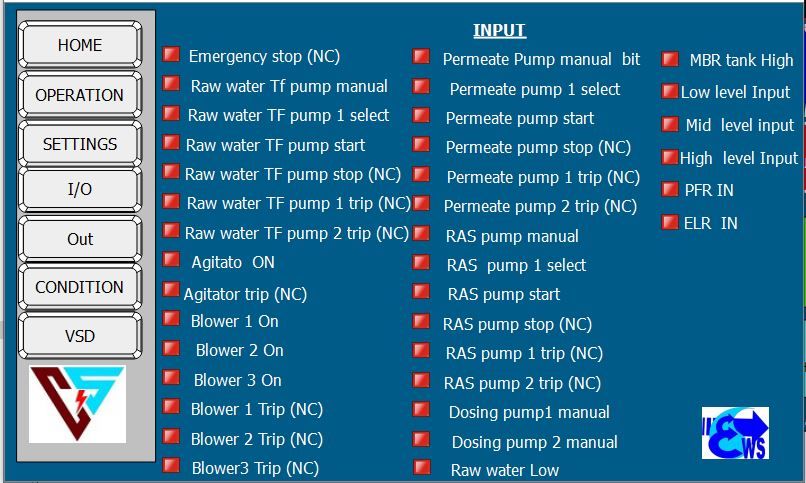

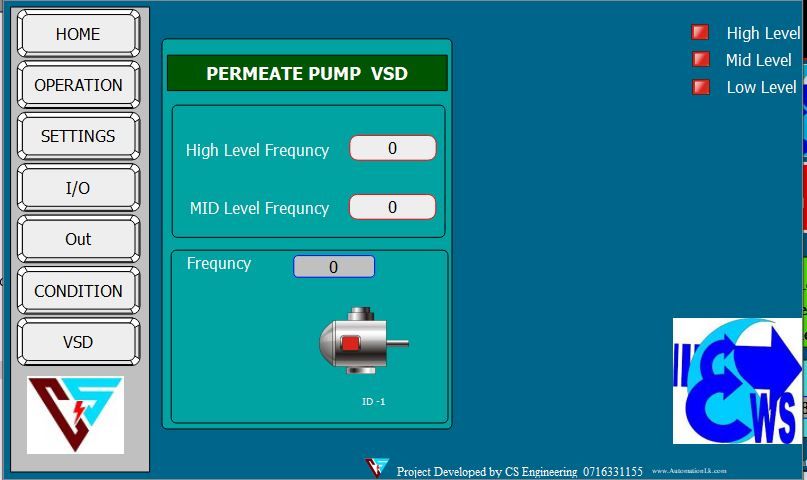

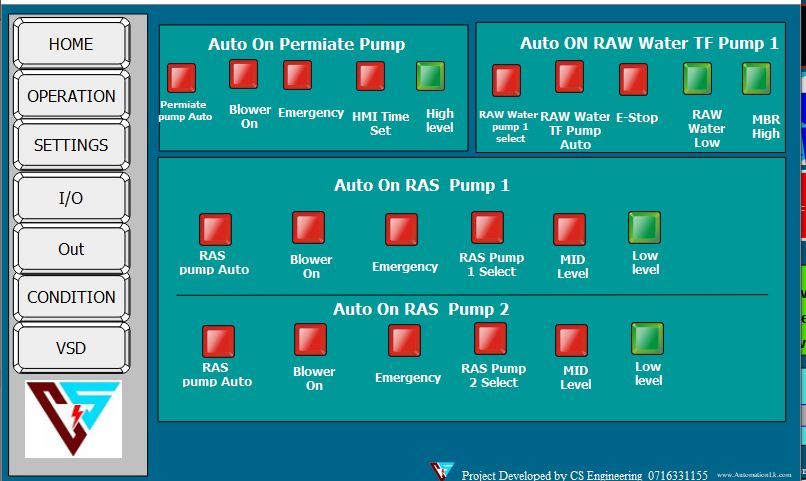

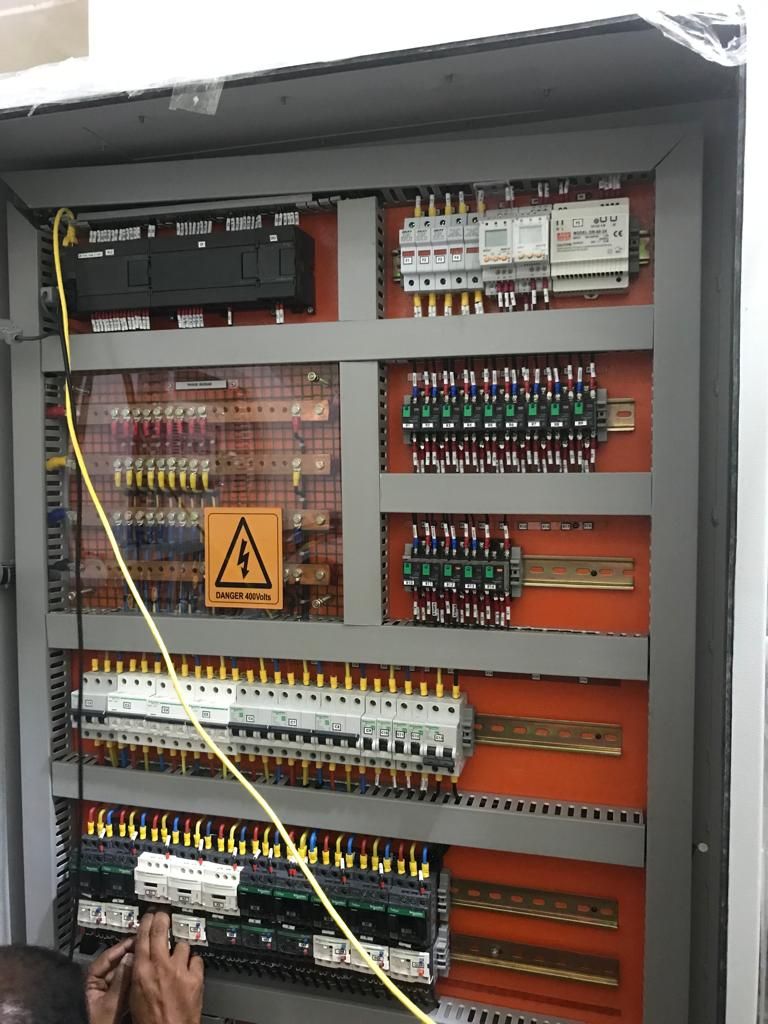

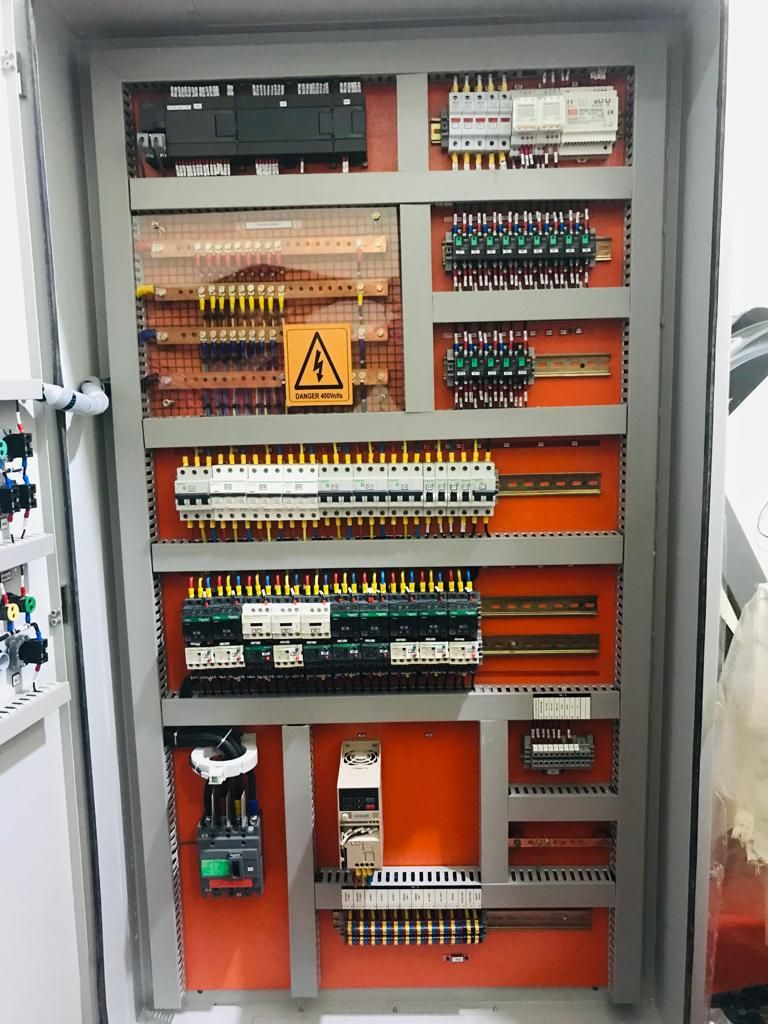

Successfully completed automation project MBR Sewage Treatment plant at Rockland Distillery Bottling Plant , Hanwella, Sri Lanka . This treatment plant include SIEMENS S7 200 PLC , Unimat 7 inch HMI and Veichi Ac10 VSD . There is the Modbus Rs485 communication between PLC and 2 VSD. All parameters of VSD (Speed,RPM,Current,Fault) can be monitoring controlling Using HMI.

Client – Rockland Distilleries (Pvt) Ltd, Hanwella

Main Contactor – Enviro Water System Pvt

Automation project MBR Sewage Treatment plant at Kenola Hospital, Anuradapura, Sri Lanka

Successfully completed automation project MBR Sewage Treatment plant at Kenola Hospital, Anuradapura, Sri Lanka . This treatment plant include SIEMENS S7 200 PLC , Unimat 7 inch HMI and Vichie Ac10 VSD . There is the Modbus Rs485 communication between PLC and 2 VSD. All parameters of VSD (Speed,RPM,Current,Fault) can be monitoring Using HMI.

Client – Kenola Hospital, Anuradapura

Main Contactor – Enviro Water System Pvt

hashtag#PLC Automation, hashtag#MBR plant Automation, hashtag#Wastewater treatment plant hashtag#s7 200 PLC hashtag#Tia Portal hashtag#Electrical Penal board, hashtag#SIEMENS Automation, hashtag#Electrical engineering, hashtag#Automation Engineer hashtag#Water Treatment Automation, # Modbus Rs485 communication